ADVANCED CRUDE QUALITY MONITORING

|

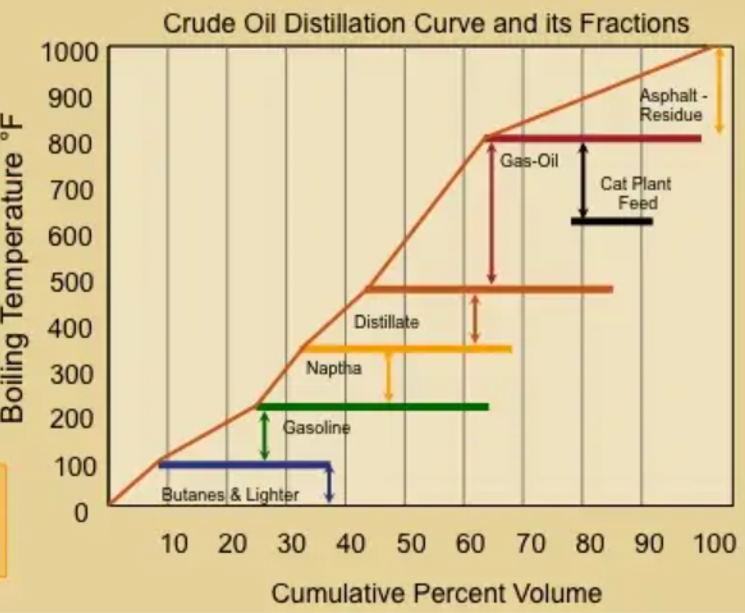

Crude it typically bought and sold on the basis of API gravity and Sulfur content - but this only tells a tiny fraction of the story. If you aren't monitoring the distillation data on each crude purchase, the crude seller can easily dump undesirable crudes and/or butane into your batch and still meet the API/Sulfur specs. RefineryU can help you set up a robust Crude Quality Monitoring program so you get what you paid for

|

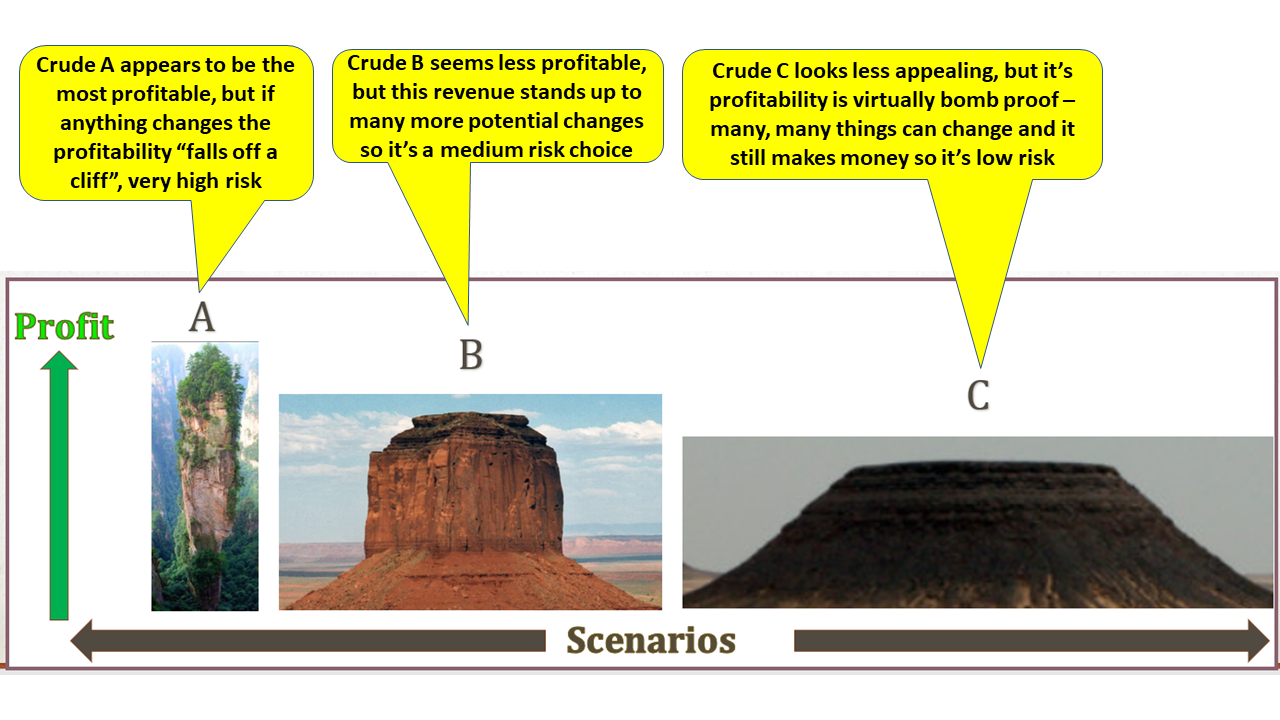

Crude Evaluation via LP Monte Carlo simulation

|

|